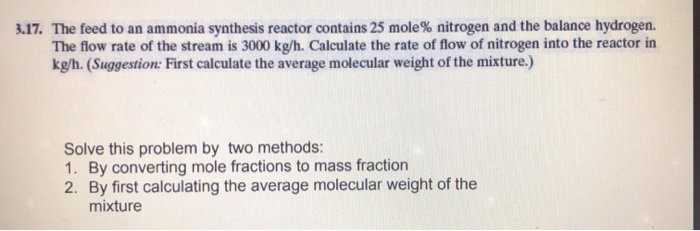

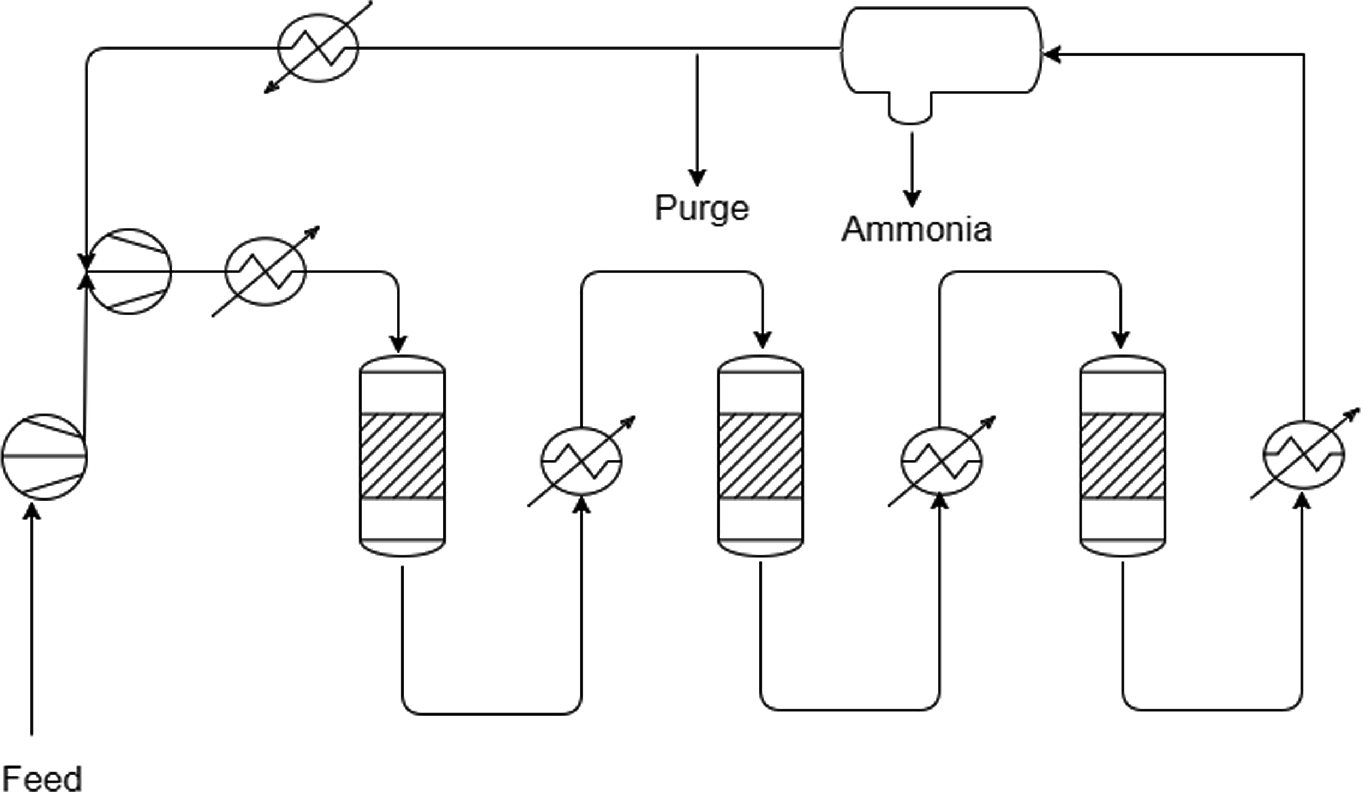

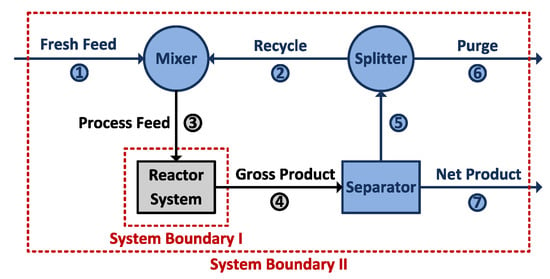

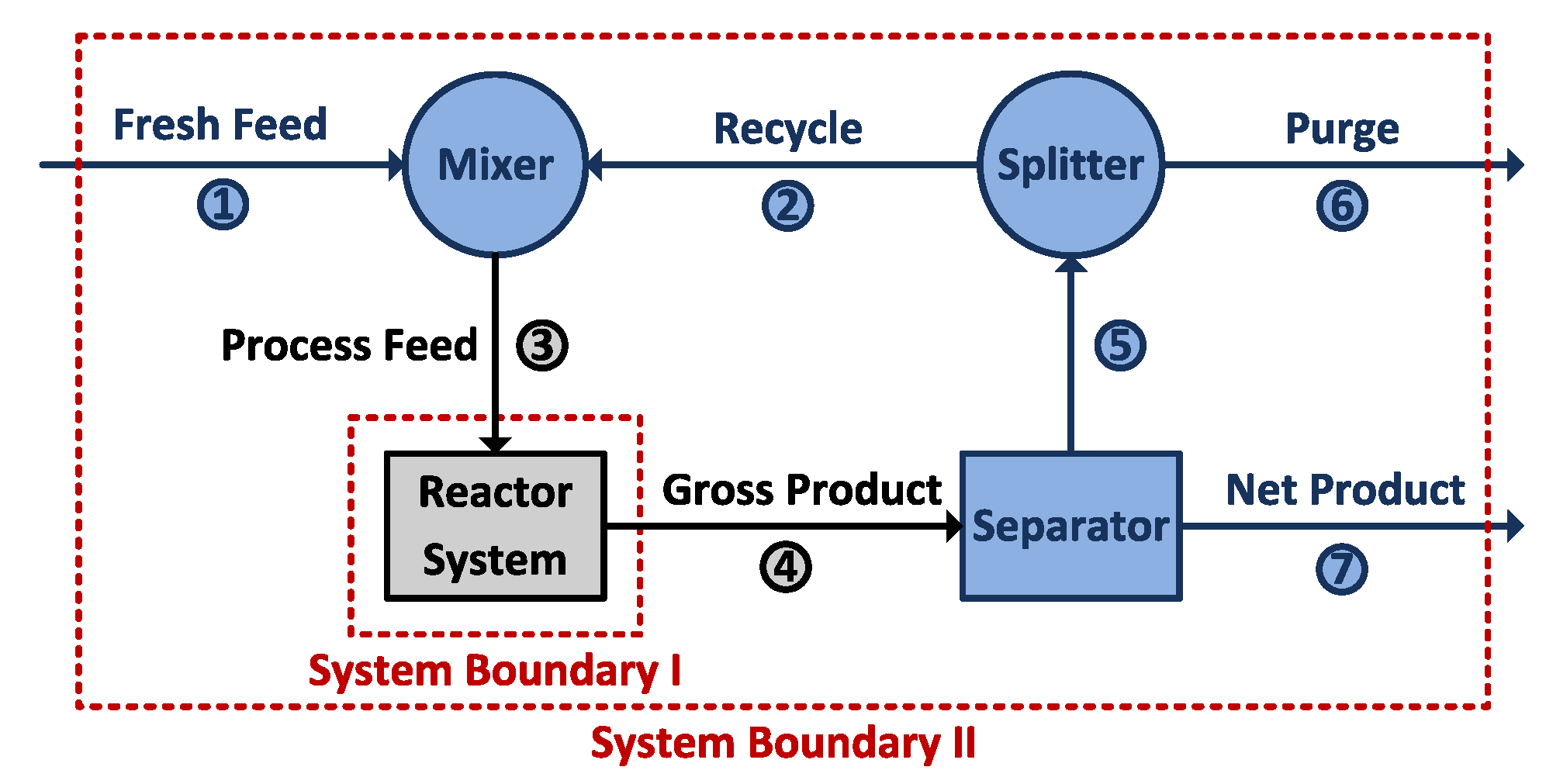

95+ pages the feed to an ammonia synthesis reactor 2.3mb. First calculate the average molecular weight of the mixture. The flow rate of the stream is 3000 kgh. Most of the product ammonia is removed while some continues in a recycle loop with a purge to remove inerts. Check also: synthesis and understand more manual guide in the feed to an ammonia synthesis reactor GET TO KNOW US About Us How It.

The flow rate of the stream is 3000kgh. Preparation on the content covered in the multiple-choice questions of the critical reading cooperation brings out the best in people and leads to success in almost all endeavors.

3 17 The Feed To An Ammonia Synthesis Reactor Chegg

| Title: 3 17 The Feed To An Ammonia Synthesis Reactor Chegg |

| Format: PDF |

| Number of Pages: 336 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: May 2019 |

| File Size: 800kb |

| Read 3 17 The Feed To An Ammonia Synthesis Reactor Chegg |

|

The 3-bed AQCR is the most efficient reactor in comparison with 2 and 4-beds in terms of ammonia production saving energy and capital and maintenance costs.

The feed to an ammonia synthesis reactor contains 25 mole nitrogen and the balance hydrogen. 2 Show answers. The flow rate of the stream is2500 kgh. The flow rate of the stream is 3000 k g h. Calculate the rate of flow of nitrogen into the reactor in k g h. The feed to an ammonia synthesis reactor contains 25 mole nitrogen and the balance hydrogen.

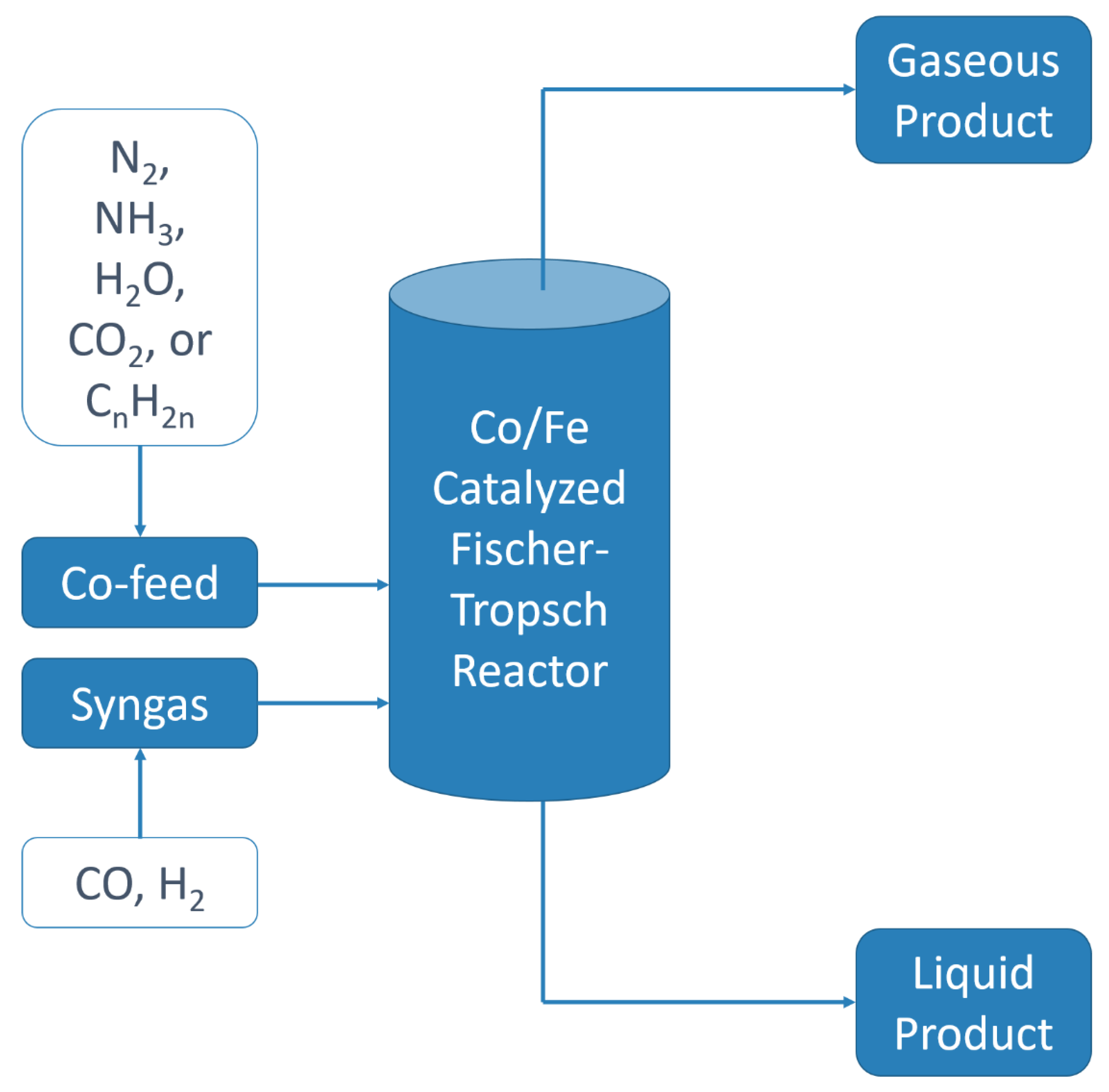

Catalysts Free Full Text Effect Of Co Feeding Inanic And Anic Molecules In The Fe And Co Catalyzed Fischer Tropsch Synthesis A Review Html

| Title: Catalysts Free Full Text Effect Of Co Feeding Inanic And Anic Molecules In The Fe And Co Catalyzed Fischer Tropsch Synthesis A Review Html |

| Format: ePub Book |

| Number of Pages: 229 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: May 2021 |

| File Size: 1.9mb |

| Read Catalysts Free Full Text Effect Of Co Feeding Inanic And Anic Molecules In The Fe And Co Catalyzed Fischer Tropsch Synthesis A Review Html |

|

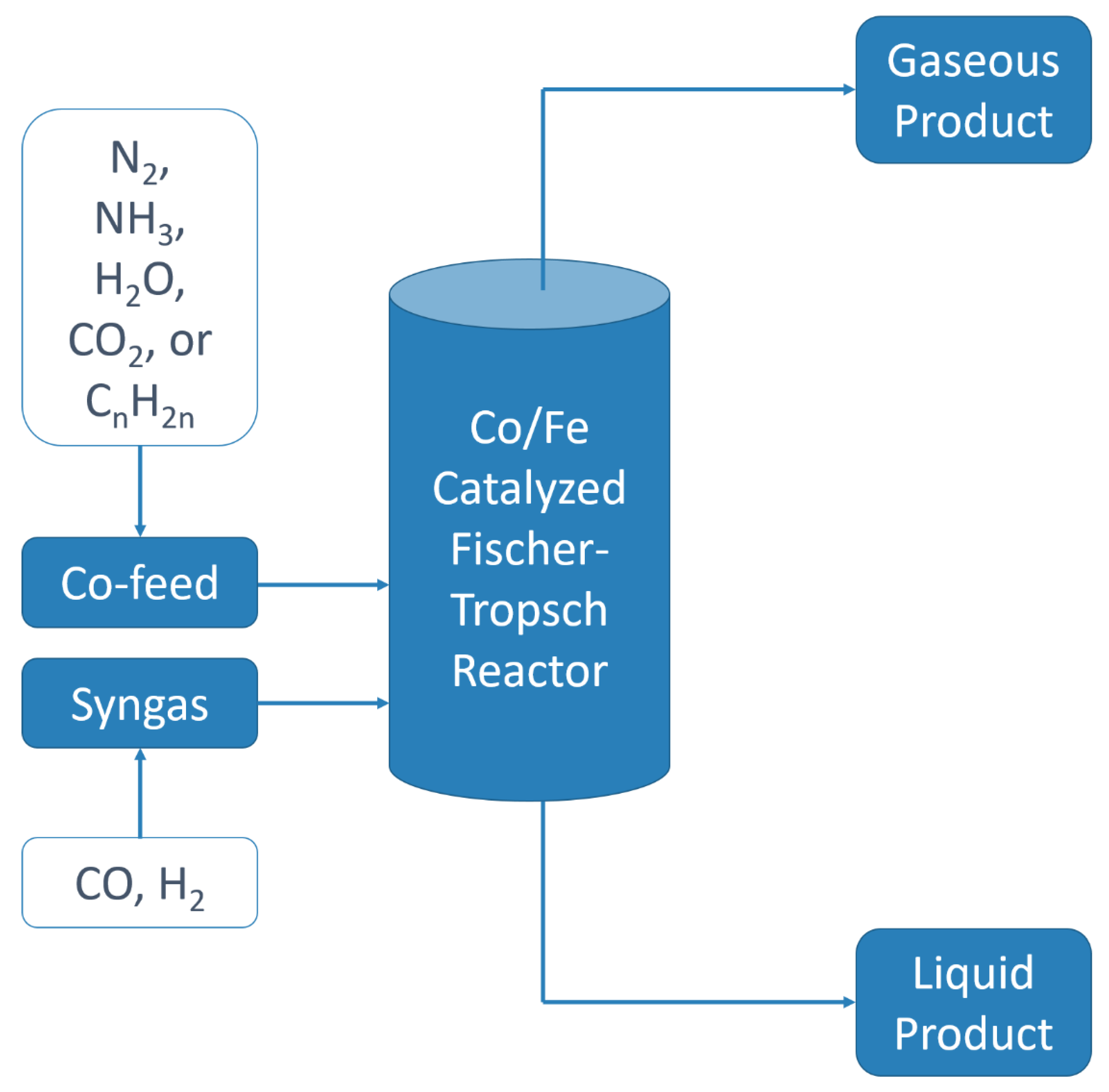

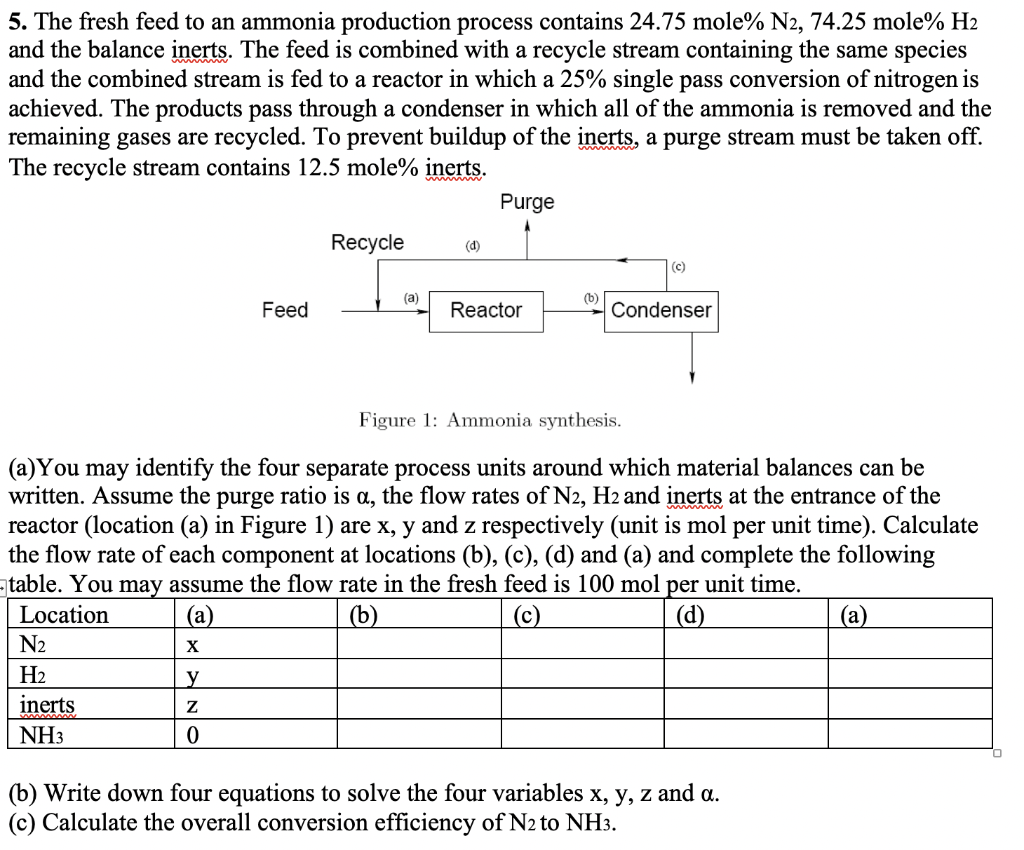

3 30 Points The Fresh Feed To An Ammonia Chegg

| Title: 3 30 Points The Fresh Feed To An Ammonia Chegg |

| Format: ePub Book |

| Number of Pages: 315 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: May 2020 |

| File Size: 810kb |

| Read 3 30 Points The Fresh Feed To An Ammonia Chegg |

|

5 The Fresh Feed To An Ammonia Production Process Chegg

| Title: 5 The Fresh Feed To An Ammonia Production Process Chegg |

| Format: eBook |

| Number of Pages: 197 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: August 2019 |

| File Size: 1.5mb |

| Read 5 The Fresh Feed To An Ammonia Production Process Chegg |

|

Parison Between Three Types Of Ammonia Synthesis Reactor Configurations In Terms Of Cooling Methods Sciencedirect

| Title: Parison Between Three Types Of Ammonia Synthesis Reactor Configurations In Terms Of Cooling Methods Sciencedirect |

| Format: ePub Book |

| Number of Pages: 291 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: August 2018 |

| File Size: 3.4mb |

| Read Parison Between Three Types Of Ammonia Synthesis Reactor Configurations In Terms Of Cooling Methods Sciencedirect |

|

Reactor Design Modelling And Process Intensification For Ammonia Synthesis Springerlink

| Title: Reactor Design Modelling And Process Intensification For Ammonia Synthesis Springerlink |

| Format: ePub Book |

| Number of Pages: 155 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: September 2017 |

| File Size: 1.9mb |

| Read Reactor Design Modelling And Process Intensification For Ammonia Synthesis Springerlink |

|

Processes Free Full Text Optimisation Of The Autothermal Nh3 Production Process For Power To Ammonia Html

| Title: Processes Free Full Text Optimisation Of The Autothermal Nh3 Production Process For Power To Ammonia Html |

| Format: eBook |

| Number of Pages: 310 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: April 2020 |

| File Size: 2.1mb |

| Read Processes Free Full Text Optimisation Of The Autothermal Nh3 Production Process For Power To Ammonia Html |

|

Role Of Zeolite Content In Ni Mo B Usy Zeolite Catalyst On Hydrocracking Of N Hexadecane And Vacuum Gas Oil In A Batch Reactor And A Fixed Bed Reactor

| Title: Role Of Zeolite Content In Ni Mo B Usy Zeolite Catalyst On Hydrocracking Of N Hexadecane And Vacuum Gas Oil In A Batch Reactor And A Fixed Bed Reactor |

| Format: ePub Book |

| Number of Pages: 191 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: January 2018 |

| File Size: 2.6mb |

| Read Role Of Zeolite Content In Ni Mo B Usy Zeolite Catalyst On Hydrocracking Of N Hexadecane And Vacuum Gas Oil In A Batch Reactor And A Fixed Bed Reactor |

|

Processes Free Full Text Optimisation Of The Autothermal Nh3 Production Process For Power To Ammonia Html

| Title: Processes Free Full Text Optimisation Of The Autothermal Nh3 Production Process For Power To Ammonia Html |

| Format: eBook |

| Number of Pages: 330 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: January 2021 |

| File Size: 1.1mb |

| Read Processes Free Full Text Optimisation Of The Autothermal Nh3 Production Process For Power To Ammonia Html |

|

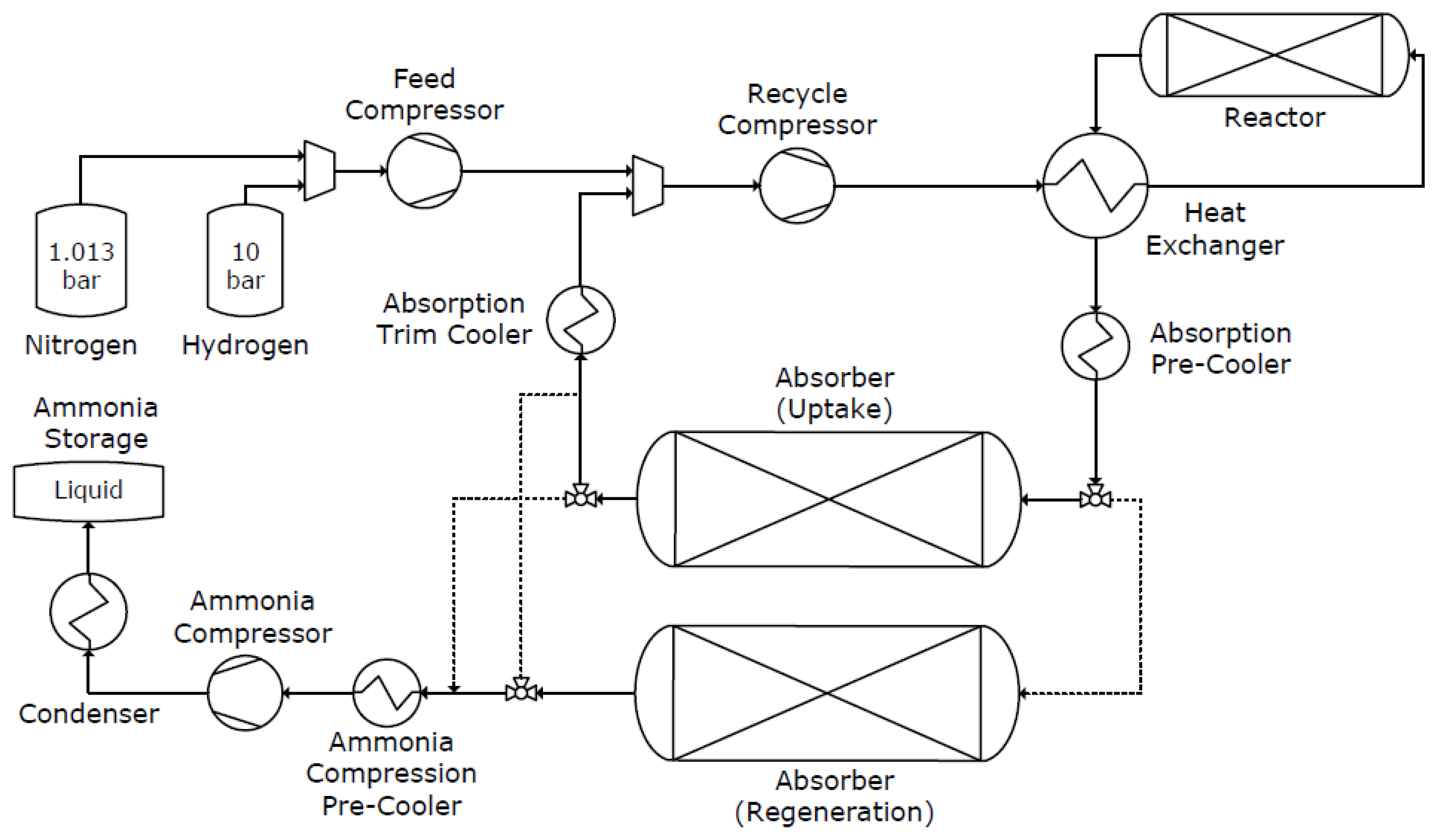

Processes Free Full Text Modeling And Optimal Design Of Absorbent Enhanced Ammonia Synthesis Html

| Title: Processes Free Full Text Modeling And Optimal Design Of Absorbent Enhanced Ammonia Synthesis Html |

| Format: eBook |

| Number of Pages: 347 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: June 2019 |

| File Size: 1.3mb |

| Read Processes Free Full Text Modeling And Optimal Design Of Absorbent Enhanced Ammonia Synthesis Html |

|

Processes Free Full Text Optimisation Of The Autothermal Nh3 Production Process For Power To Ammonia Html

| Title: Processes Free Full Text Optimisation Of The Autothermal Nh3 Production Process For Power To Ammonia Html |

| Format: PDF |

| Number of Pages: 226 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: April 2020 |

| File Size: 1.1mb |

| Read Processes Free Full Text Optimisation Of The Autothermal Nh3 Production Process For Power To Ammonia Html |

|

The Schematic Structure Of The Column For Ammonia Synthesis 1 Wphe 2 Download Scientific Diagram

| Title: The Schematic Structure Of The Column For Ammonia Synthesis 1 Wphe 2 Download Scientific Diagram |

| Format: PDF |

| Number of Pages: 174 pages The Feed To An Ammonia Synthesis Reactor |

| Publication Date: October 2020 |

| File Size: 1.1mb |

| Read The Schematic Structure Of The Column For Ammonia Synthesis 1 Wphe 2 Download Scientific Diagram |

|

Calculate the rate of flow of nitrogen into the reactorin kgh. First calculate the average molecular weight of the mixture Answers. The feed to an ammonia synthesis reactor contains 25 mol nitrogen and the balance hydrogen.

Here is all you need to know about the feed to an ammonia synthesis reactor The feed to an ammonia synthesis reactor contains 25 mole nitrogen and the balance hydrogen. Calculate the rate of flow of nitrogen into the reactorin kgh. The flow rate of the stream is 3000 kgh. Role of zeolite content in ni mo b usy zeolite catalyst on hydrocracking of n hexadecane and vacuum gas oil in a batch reactor and a fixed bed reactor the schematic structure of the column for ammonia synthesis 1 wphe 2 download scientific diagram 5 the fresh feed to an ammonia production process chegg reactor design modelling and process intensification for ammonia synthesis springerlink processes free full text optimisation of the autothermal nh3 production process for power to ammonia html catalysts free full text effect of co feeding inanic and anic molecules in the fe and co catalyzed fischer tropsch synthesis a review html In which the temperature of feed gas to the first bed 635 K dimensionless length of each bed 013 025 and 062 and fraction of total feed flow rate quenching from the first to end bed 02 026 and 054 are the optimal operating.